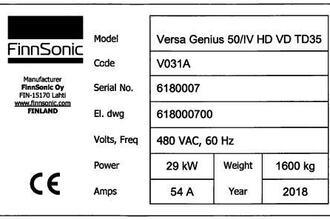

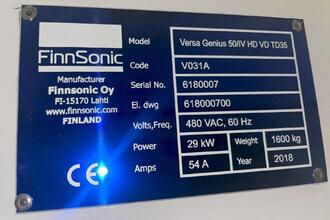

Finnsonic Versa Genius+ 50/IV HD VD TD35 Ultrasonic Parts Cleaner, New 2018

Ultrasonic Washers and Cleaning Systems

Finnsonic Versa Genius+ 50/IV HD VD TD35 Automatic 6-Stage, 8-station fully Automatic Ultrasonic Parts Cleaner, new 2018

Robotic Transfer, Roller Conveyor, Load/Unload Stations

=================== EASILY CONVERT TO USING A PASSIVATION PROCESS ========================

Finnsonic CNC Control System

2013 Ferroplan Roller Conveyor (s/n: 9998-21-51800)

NOTE: Ultrasonics Hertz can be increase with an in-tank upgrade, ask for more information

Approximate new replacement cost $ 225,000.00

| Tank-W | 8.75" |

| Tank-L | 16.68" |

| Tank-H | 7.88" |

| Number of Tanks | 6 |

| Transfer System? | Yes |

| Control | CNC (Siemens Simatic HMI) |

| Dimensions | 234" l x 144"D x 117"H |

To the best of our knowledge all details listed below are deemed correct.

It is the buyer’s responsibility to confirm all details and we encourage an inspection of the machine(s) and accessories prior to purchase.

Finnsonic Genius 50IV: 8-Stage, 6-tank Fully Automatic Ultrasonic Cleaning System

this system is designed for less max weight per basket & quicker processing times

======================================================================================

Basket internal dimensions: 220 x 415 x195(h) mm (8-3/4" x 16-5/8" x 7-7/8"h)

Max load kg 10 kg (22 lbs.)

Liquid volume/tank 45 l (approx 12 gal)

Ultrasonic power/tank 600 W, transducers on tank base

Heating power 2 kW / tank, 4 kW / hot air dryer

Process direction --- left to right as a standard

Voltage (VAC) 480 V three phase, 60 Hz (transformer required

for any other voltage)

Cable marking Level 2, according to FinnSonic technical specification TS15

Ventilation connection Ø150 mm

Compressed air 5-7 bar, dry and filtered

Space requirement for the line & service ca. 6017 x 3690 x 2980(h) mm,

pumps located under the conveyors

Noise level 75 ± 3 dBA

Takt time Total throughput of baskets depends on required

cleaning and drying times. Due to several process

variables, no exact capacity figure can be

confirmed without further testing.

Process stages and functional units

Process direction from left to right

Stage 1

- ultrasonic cleaning, 1200 W, 30 kHz

- basket dunk for vertical agitation

- storage tank, located inside the machine encapsulation

- auto stop/go control for storage tank circulation

- Belki 211 oil separator

- surface spray bar

- 20” stainless filter with 50µ cartridge for fine filtration

- auto refill

- auto detergent dosing

Stage 2

- ultrasonic cleaning 1200 W, 30 kHz

- basket dunk for vertical agitation

- Closed loop filtration with 20” stainless filter with 50µ cartridge for

fine filtration

- auto stop/go control for closed loop circulation

- auto refill

- auto detergent dosing

Stage 3

- jet spray under immersion

- Closed loop filtration with 20” stainless filter with 50µ cartridge for

fine filtration

- autopurge

Stage 4

- rinse with deionized water

- closed loop deionized water filtration with resin and active carbon filters and

20” stainless filter with 50µ cartridge for fine filtration

- conductivity measurement, measuring range 1micS-1mS

Stage 5

- hot air dryer

- automatic sliding lid to left

Stage 6

- vacuum dryer

Other items included:

- Siemens PLC

- TD35 automatic basket transporter

- full encapsulation with plexi windows, interlocked rear service doors

- filtermist steam condenser

- motorized loading and unloading conveyors, space for 4 baskets on each conveyor

- cooling station with covering for the unloading conveyor

- light beacon

- wash baskets (10 pcs) for Versa Genius 50, with support for customer’s plastic

jigs for blades

- usage meters for water, air and power

- Common water inlet and drain connections for all the stages

- drain pump, 8m vertical delivery

- calibration certificates for temperature sensors and pressure meters

- seaworthy packing

Note: see dowload the pdf technical brochure for more details