New Spindle Liners

TOOLING & ACCESSORIES, N/C & CNC

New Spindle Liners

NEW Spindle Liners from JF Berns:

Spindle liners (also referred to as filler tubes, reductions

tubes or master liners), are used to reduce the I.D. of a CNC lathe spindle,

usually to .030-.060" over the diameter of the bar being machined. The result

is faster machining speeds and closer machining tolerances. They are used in

lathes often in conjunction with barfeeders, bar loaders and bar pullers.

Easy to order: Minimal information required - usually just lathe make & model

Ready to use: Includes mounting holes, screws for attaching to the lathe,

adapters if required, and stock size marked on every spindle liner. No

drilling is required!

Free Extensions: When required to increase lathe bar stock length capacity

Variety of Materials: Steel; Hybrid Style of Steel & Urethane (patent

pending); Phenolic; Nylatron & more.

Any Stock Shape: Liners can be made for hex, square, irregular shapes, etc.

Options: Liners can be honed to special IDs, hardened, lined with non-metal

materials and more.

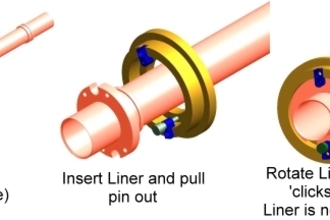

Quick Change Spindle Liners: With this patented system, a spindle liner can be

exchanged in a matter of seconds without tools or loose pieces such as screws

or retaining rings. After inserting the liner through the adapter into the

lathe, rotating the liner 30 degrees puts it into the locked position and the

spring loaded pull pin keeps liner in place until the next change is made.

The price of quick change spindle liner is the same as our standard liners.

Each CNC Lathe will require the purchase of one quick change adapter.

The FACTS on Metal Spindle Liners

They can be made with extensions to increase the lathe spindle capacity

The weight of the spindle liner is negligible compared to the capacity of the

lathe and does not increase spindle bearing or drive wear - they also do not

decrease the maximum turning speed of the lathe.

They can be made with extremely thin walls to maximize the capacity of the

lathe

Less likely than non-metal liners to 'pickup' metal chips that can scratch the

part

Metal spindle liners can be hardened to 70 rockwell for even less scratching

potential

Extremely durable

Little to no vibration when sized properly

We offer the patented Quick Change Spindle Liners for no tool changeovers

Because the spindle liner rotates with the stock, metal to metal contact does

not create any noise louder than the lathe itself

Metal spindle liners are quickly re-workable

Specials (such as 2 or 3 part liners) can be designed and manufactured

Also available:

Spindle Liner Racks.... $ POR